ORAL

ELECTRICAL

ELECTRONICS

AUXILIARY MACHINERY

BATTERY

Recent posts

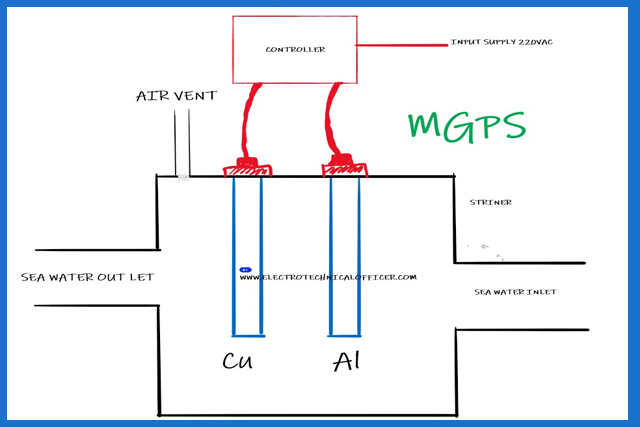

View allShort notes of MGPS | ETO ORAL

Contents MGPS – Marine Growth Prevention System The seawater system is protected against fouling by the anti-fouling system. The system protects against marine growth and corrosion…

Procedure for the Operation of Shore Power | Questions & Answers

Contents Shore Power Shore supply is used mainly during dry dock when alternator have to overhaul Nowadays shore power is used for emission control in ports Introduction …

Marine alternator oral questions and answers |ETO| Marine Electrical

Contents What will happen if we overexcite the alternator? OR If we overexcite what will happen to the power factor? If the generator overexcited so and it will supply a l…

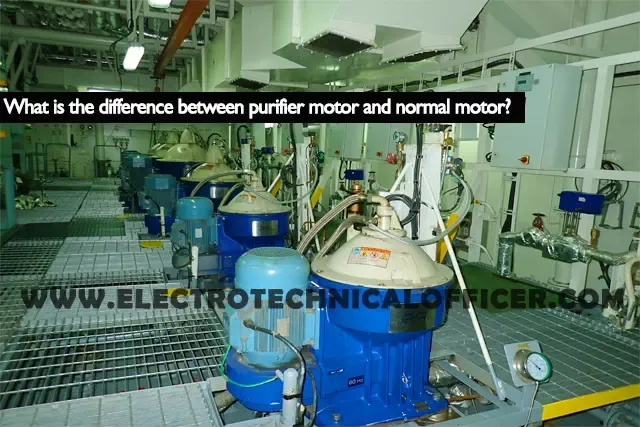

What is the difference between the purifier motor and normal motor?

Contents What kind of motor used for antenna drives? (Furuno Radars) X-band Radar - DC Motor S-Band Radar – Three Phase Induction Motor Where is Dc motor used onboard? …

NAVIGATIONAL SYSTEMS

WRITTEN

ETO

Total Pageviews

Popular Posts

ETO COC NUMERICAL QUESTIONS AND ANSWERS - SOLVED I

How will you check AVR? (AUTOMATIC VOLTAGE CONTROLLER)

Short notes of MGPS | ETO ORAL

Featured Post

MGPS

MGPS

Short notes of MGPS | ETO ORAL

Contents MGPS – Marine Growth Prevention System The seawater system…

Social Plugin